Extending Machine Life & Improving Performance With Sorbothane

Viscoelastic Vibration Isolators and Shock Absorbers

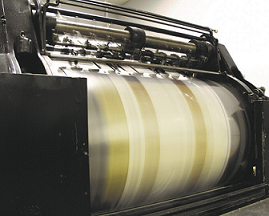

Damaging vibration, shock and even unwanted noise are a fact of life with rotating and oscillating machinery. Both shock and vibration can cause moderate to severe damage to equipment – increasing operating costs, reducing productivity and adversely effecting part quality.

Damaging vibration, shock and even unwanted noise are a fact of life with rotating and oscillating machinery. Both shock and vibration can cause moderate to severe damage to equipment – increasing operating costs, reducing productivity and adversely effecting part quality.

Motion is present in all industrial automation systems. Stopping or changing the direction of that motion releases kinetic energy, which can cause shock and vibration to occur. Any sudden shock in a system can cause immediate damage to the overall machine and the components being processed. Consistent vibration inputs can cause damaging fatigue over time. This is why it’s necessary to decelerate a system smoothly through the use of energy dissipating components.

Energy Dissipation Assessment

Manufacturing engineers and operators have long addressed energy dissipation and the need to isolate damaging vibration and attenuate machine-generated shock. As a result, machine mounts of various designs and materials have been developed and tested to address the problem. Energy control and dissipation, when correctly applied, have proven to extend the life of the machine and and improve its efficiency.

Every part in a machine is designed to perform a specific role. Each part needs to work together toward the primary function of the machine. But individual parts can work against each other and defeat the overall purpose when there is too much vibration generated. The energy that is being generated to provide the required action is dissipated so the machine has to work harder and longer to perform its job. Eventually, that will wear the parts out and cause them to be weaker and more likely to break. Once one part of the machine work incorrectly, most are broken.

Identify The Vibration Isolation Problem

Vibration is the mechanical phenomenon of oscillations occurring around a point of equilibrium. Any mass with elasticity can vibrate; elasticity is the tendency of the mass to return to its original size, shape or position after the applied force has been removed. In the manufacturing world, vibration forces are generated by rotating and oscillating motions of the type found in lathes, conveyors and similar equipment. Shock differs from vibration in that it results from a sudden impact, as opposed to the application of a repeating periodic force. Shock is a stimulus applied directly to a system. A mechanical shock is a sudden deceleration or acceleration.

Vibration is the mechanical phenomenon of oscillations occurring around a point of equilibrium. Any mass with elasticity can vibrate; elasticity is the tendency of the mass to return to its original size, shape or position after the applied force has been removed. In the manufacturing world, vibration forces are generated by rotating and oscillating motions of the type found in lathes, conveyors and similar equipment. Shock differs from vibration in that it results from a sudden impact, as opposed to the application of a repeating periodic force. Shock is a stimulus applied directly to a system. A mechanical shock is a sudden deceleration or acceleration.

Examples of Shock:

-

- A crash

-

- A drop

-

- A strike

-

- An earthquake

-

- An explosion

To reduce the amount of dissipated energy along the parts inside of a machine, there needs to be a way to lower the amount of disturbance that has been created. The energy can then be transferred to the individual parts without the dissonance and loss of energy. The machine will not only work more efficiently, but also may perform for an extended period. The loss of time and production from breakdowns and repairs will be reduced significantly.

Application of the proper vibration isolating or shock attenuating components requires not only an understanding of the causes of vibration and shock but also an understanding of the characteristics of the available mount options.

SORBOTHANE® Effectively Damps Vibration and Attenuates Shock

Viscoelastic Sorbothane has the ability to damp and isolate vibration along with attenuating shock loads. Sorbothane components – pads, mounts, bushings and washers dissipate energy in a variety of applications. The geometry, thickness and durometer of the Sorbothane® parts must be tailored to meet specific design requirements.

Common uses include:

-

- Lab and testing equipment

-

- Consumer appliances

-

- Aerospace

-

- Foundations for presses

-

- Production machinery

-

- Impact plates

Sorbothane attenuates shock with near-faultless memory, which means its deformation is elastic. The elastic pads allow the material to reliably return to their original shape. Custom and standard parts made of Sorbothane® work for vibration damping and isolation, acoustic damping and shock attenuation. Sorbothane® works by turning mechanical energy into a small amount of heat as the material is deformed. The applied force is then translated perpendicularly away from the axis of incidence.

Accurately Predicting Natural and Disturbance Frequency

Accurately predicting the natural frequency of an application lets shock and vibration engineers target known disturbance frequencies to dissipate unwanted energy. The lower the ratio of natural system frequency to disturbance frequency, the more it is possible to isolate dangerous problem vibrations.

Sorbothane components work to isolate vibrations and dissipate shock. They are also engineered and produced in a variety of shapes, sizes and durometers.

Sorbothane components work to isolate vibrations and dissipate shock. They are also engineered and produced in a variety of shapes, sizes and durometers.

Every Sorbothane part is specific to the client’s design and function requirements. Contact Sorbothane, Inc. for design and engineering assistance.

Learn More About:

Impact of Shock Absorption

Vibration in Engineered Designs