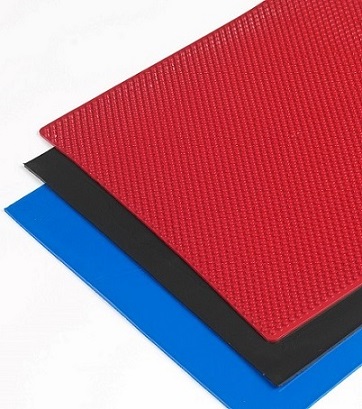

Sorbothane Sheet Stock: The Perfect Impact Absorbing Material

Sorbothane® Sheet Stock offers a quick and effective method for isolating a wide variety of loads and equipment. It is available in a variety of sizes, from 4” X 6” to 25” X 25”, and a wide range of thicknesses and durometers. It can support a broad range of loads. The proper thickness, durometer, shape and size are required for maximum efficiency.

The aggressive, pressure-sensitive adhesive available on Sorbothane Sheet Stock features a thin polyester film for improved handling and dimensional stability. The adhesive on sheet stock has remarkable temperature and chemical resistance. A strong bond is created with the right amount of adhesive-to-surface contact and firm application pressure. Sorbothane is the perfect impact absorbing material that can be used to create an impeccable anti vibration pad.

Options for Customizing Sorbothane Sheet Stock

Sheet stock can be knife-cut, scissor-cut, die cut or water jet cut.

Die Cutting

Sheet stock of up to a thickness of 0.25 inch, with or without PSA, can be factory die cut. Die cut materials will have a concave edge.

Water Jet Cutting

Sheet stock of any thickness can be water jet cut and will have a clean edge.

Gaskets

Sorbothane is a desired material for gaskets because of its chemical resistance, conformability to irregular surfaces, low creep factor and reusability. Its natural tackiness makes installation easy. Gaskets can be scissor-cut, knife-cut, die cut, molded or water jet cut.

X-Tra Flex Sheet

X-Tra Flex Sheet is molded with hemispherical bumps. The hemispheres allow the material to flex more easily and provide soft deformation under load. Overall sheet thickness is approximately 0.19-inch. The hemispheres are approximately 0.09” high and 0.12” in diameter. X-Tra Flex sheets are often used for curves or irregular surfaces.

Sorbothane Offers Special Sizes, Colors and Thicknesses

At Sorbothane, we pour special shapes, colors and thicknesses of our sheet stock.

Using Sheet Stock for Vibration Applications

When designing your own vibration mounts from sheet stock, consider the following:

More is not always better – A large, lightly loaded sheet will have a high spring rate. It will not deflect enough to provide good vibration isolation. Over compression can lead to short service life. The proper compression range is 3 to 20 percent, depending on the “Shape Factor.” Shape factor is the ratio of contact surface (one side) divided by perimeter area.

Geometry matters – Small circular pieces and rings “bulge” better than squares and rectangles, which makes for better isolation. Use several small discs rather than large rectangles for the best vibration isolation performance.

Thickness matters – The thicker a sheet is, the lower the natural frequency. A sheet at least one-inch thick is needed to reduce natural frequency to 10 Hertz. (10 Hertz is the target natural frequency for a 900-RPM motor.)

Do not “bolt through” your Sorbothane Sheet – This is because the bolt will carry the vibration to the base. Use the natural tackiness of Sorbothane, or apply an adhesive to glue the Sorbothane® to metal plates on both sides. Or, consider a custom design with molded-in stud mounts.

Use vibration-rated connections – Where bolted connections are used, use high-quality (thread deforming) lock nuts or doubled jam nuts to prevent connections from vibrating loose.

Consult the Sorbothane Engineering Design Guide or the factory for additional information.